To Manufacture innovative building industry architectural oriented products for our clients & to provide them under one roof all façade and landscaping finishing products.

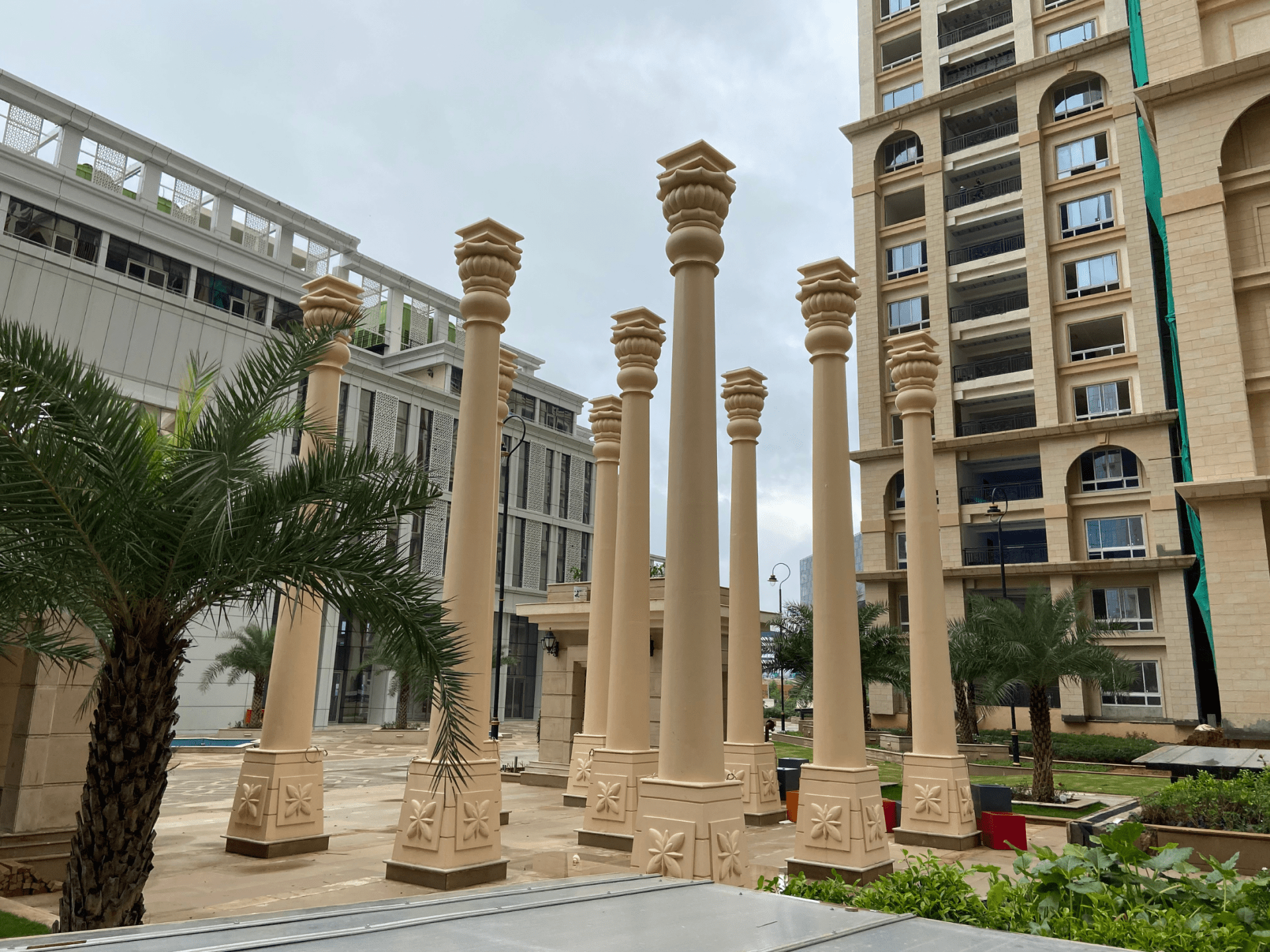

GRC is used to produce architectural features like columns, capitals, brackets, moldings, cornices, pedestals, handrails, balusters, window & door surroundings, arches and a lot more. GRC’s ability to be molded in complex shapes and contours and replicate fine details makes this material an ideal choice for architects and engineers. Whilst often cast with thickness in excess of 25mm, these products remain easy to handle and erect, and permit the architect or engineer an unrivaled freedom for creative design.

S. No | Point of Difference | GRC | FRP |

1. | Material Description | Cement Based composite material reinforced with Alkali Resistant Glass Fibers. | Fiber reinforced plastic or Polymer made with polymer matrix reinforced with fibers |

2. | Composition | White Portland Cement, A.R.G Fiber with Zirconium dioxide – ZrO2 content of at least 16%, Fine graded sieved aggregates, clean water, UV-resistant exterior grade synthetic iron oxide pigments, Polymers & Plasticizers | ISO /UV Resistant PNG Polyester Resin, Fire retardant additives Inorganic fillers, fiber, UV resistant exterior grade synthetic iron oxide pigments and catalysts. |

3. | Weight | GRC being Solid material, carried a higher weight i.e., between 3.5 Kg – 4.5 Kg per Sq. Ft for screens, depending on design, void and desired thickness. The above considered weight is for GRC screens having 50% void, Border thickness –50mm and design membrane 30mm. | FRP being hollow and stiffeners are used only at partial areas, from where fixing is done, it carried a lower weight i.e., 1 –1.5 Kg per Sq. Ft. The above considered weight is for FRP screens having 50% void, Border projection – 50mm and design member projection 30mm & wall thickness 3 mm. |

4. | Production Methodology & Versatility | Casted in FRP Molds or rubber moulds, customized as per requirement in terms of size, thickness, levels shade and design. 3D option possibility as it is casted from molds | Cast in FRP Moulds or rubber moulds, customized as per requirement in terms of size, thickness, levels shade and design. 3D option possibility as it is cast from moulds |

5. | Shades availability | All natural shades can be made as it is pigmented with UV Resistant Synthetic inorganic exterior grade pigments, other than Blue and Green, which are not U.V stabilized | All natural shades can be made as it is pigmented with UV Resistant Synthetic inorganic exterior grade pigments, other than Blue and Green, which are not U.V stabilized |

6. | Appearance | Closest to Natural stone finish, one side finished product i.e., design can be achieved on front only, due to constraints of mold. | Fabricated or Plastic appearance from very close proximity, from a distance appears as good as GRC. It can be made single and both sided finished, as the back side is packed with same material. For matt finish matteners can be used in order to give complete matt finish. |

7. | Fire Rating | Grade A1, Non-combustible material | Grade A, resists fire wih usage of Fire retardants |

8. | Performance in Exteriors | Resistant to weather, Corrosion, Fire, Abrasion, and Termites | Resistant to weather, Corrosion, Abrasion, and Termites |

UNISTONE GRC SPRAY UP MIX CONCRETE DESIGN

S. No | Raw Material | Percentage | Batch in Kg |

1. | White Portland Cement / Ordinary Portland Cement | 47 – 48% | 48 Kg |

2. | Fine aggregates – Fine graded Sieved Silica Sand | 47 – 48% | 48 Kg |

3. | Alkali resistant Glass fibre | 3.5 - 5% | 3.5 - 5 Kg |

4. | Plasticizer | 0.5% | 0.5 Kg |

5. | Polymer | 0.9% | 0.91 Kg |

6. | UV resistant exterior grade synthetic inorganic pigments | Dosage as per approved shade | Dosage as per approved shade |

7. | Clean Water ( Water Cement Ratio 0.3 ) | 33.33% | 16 Kg |

Make your house a signature home.

UniStone’s contribution in building the nation

Enhancing Serenity at weekend getaways.

Vibrant GRC Screen work with subtle GRC stone cladding

Pleasing Aesthetics along with functionality in form of well ventilated car parking

Hospitality at its best

Permanent finishes for beautiful high rise residential towers

Modernising Metro stations with a traditional touch.

Make your house a signature home.

UniStone’s contribution in building the nation

Enhancing Serenity at weekend getaways.

Vibrant GRC Screen work with subtle GRC stone cladding

Pleasing Aesthetics along with functionality in form of well ventilated car parking

Hospitality at its best

Permanent finishes for beautiful high rise residential towers

Modernising Metro stations with a traditional touch.

Interesting façade for modern airports.

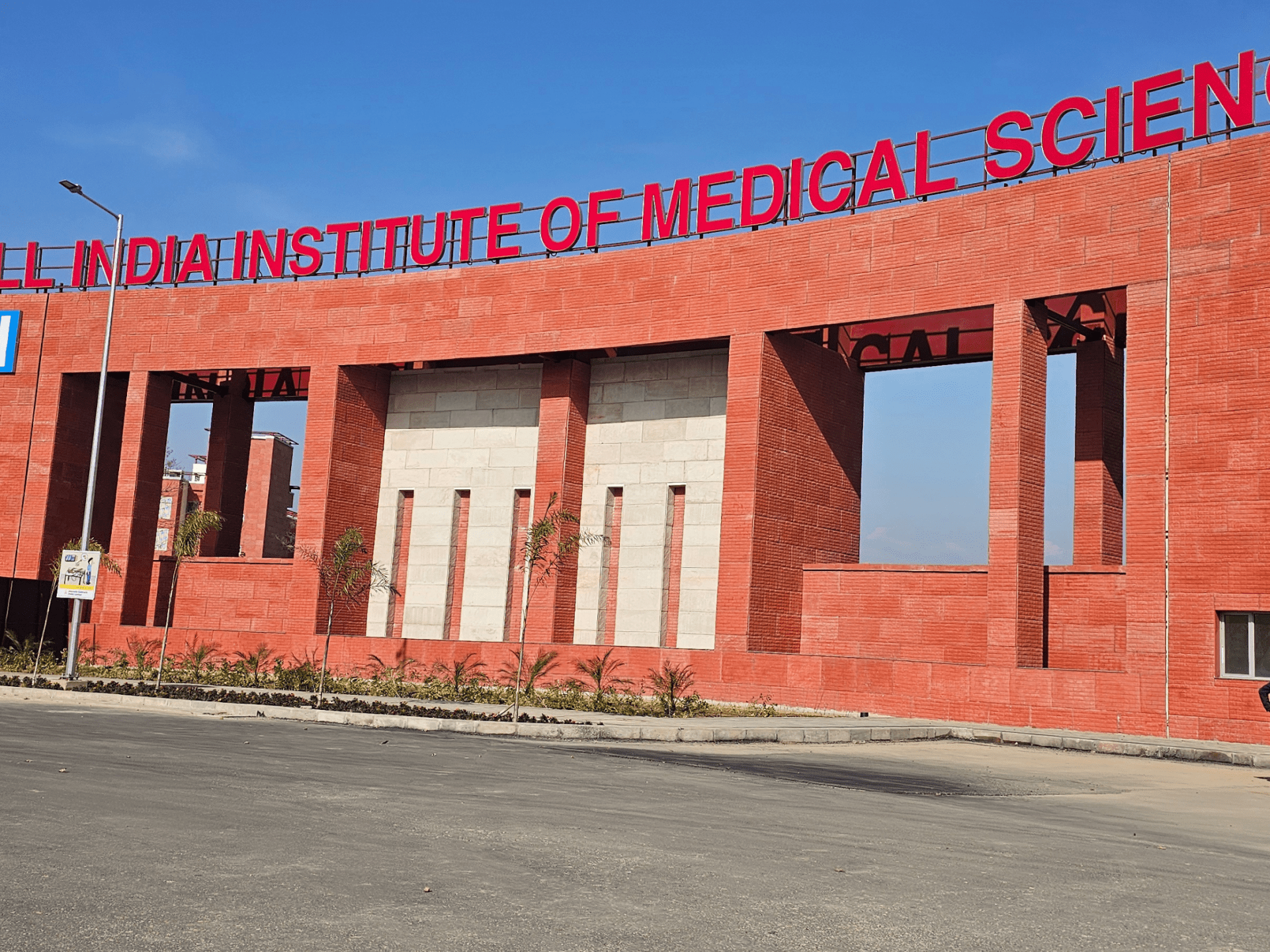

State of Art Medical Facilities

Perfectly suited to create luxury villas.

Creating special effect in urban life.

GRC :- Glass Fibre Reinforced Concrete

GFRC :- An acronym for Glass reinforced concrete used in U.S.A

GRC / GFRC :- Cement Based Composite Material reinforced with Alkali Resistant glass fibres, aggregates & Polymers

The fibres add to flexural, tensile and impact strength resulting in strong, yet light weight Architectural and Building products

Fiberglass-reinforced polyester resin plastic composite material composed of fibre reinforcements and polyester resin. Reinforcement imparts strength and stiffness, while the resin is an adhesive matrix that bonds the fibres.

Unistone, a leader in facades and paving, has pioneered innovative building solutions in India. In 1996, we introduced Reconstituted Stone, transforming architectural design. In 2007, we launched Customised GRC Products for modern construction, and in 2021, our CFP – Clay Facade Panel set new standards in energy-efficient, sustainable facades. Unistone remains at the forefront, delivering products that blend aesthetics, functionality, and durability.

17, Arihant Nagar, West Punjabi Bagh Opp. Metro Pillar No. 152-153, New Delhi - 110026

+91 8826457070, +91 8178713790

You cannot copy content of this page