Porcelain Cobble Stones

Redefining Timeless Paving

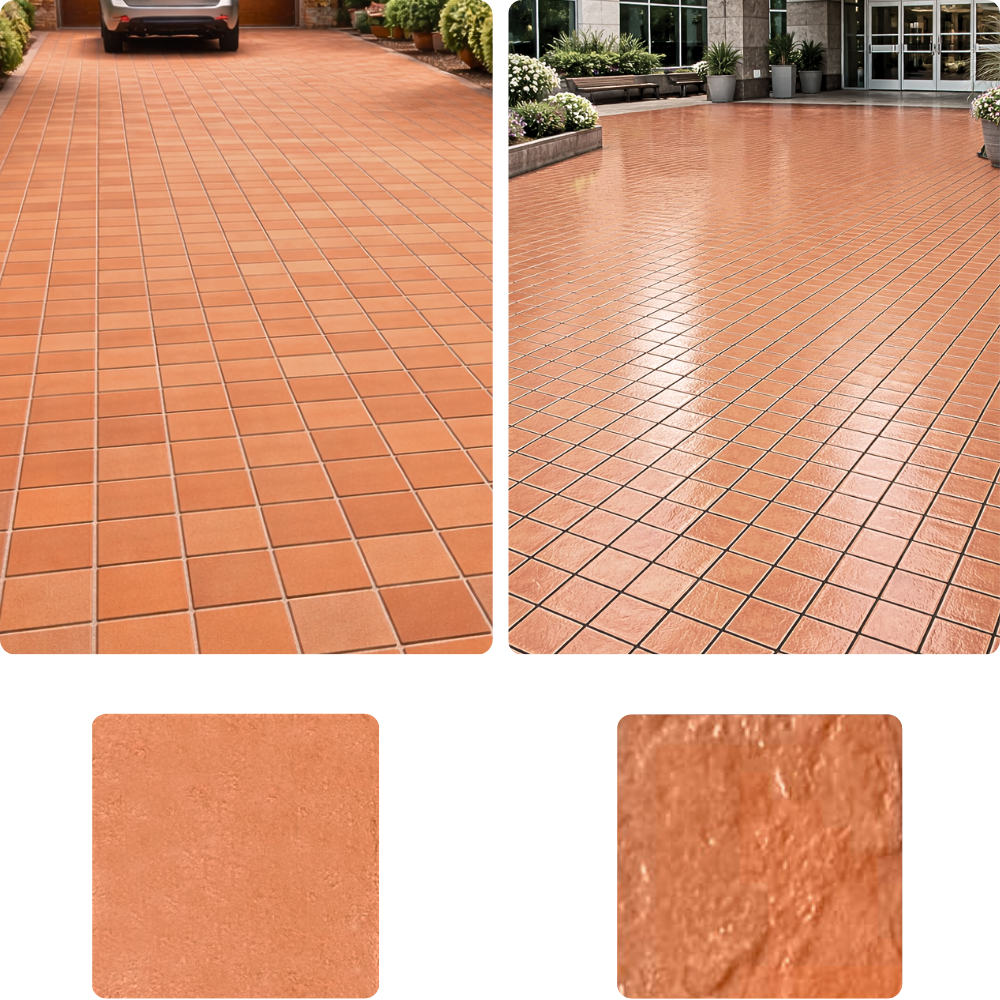

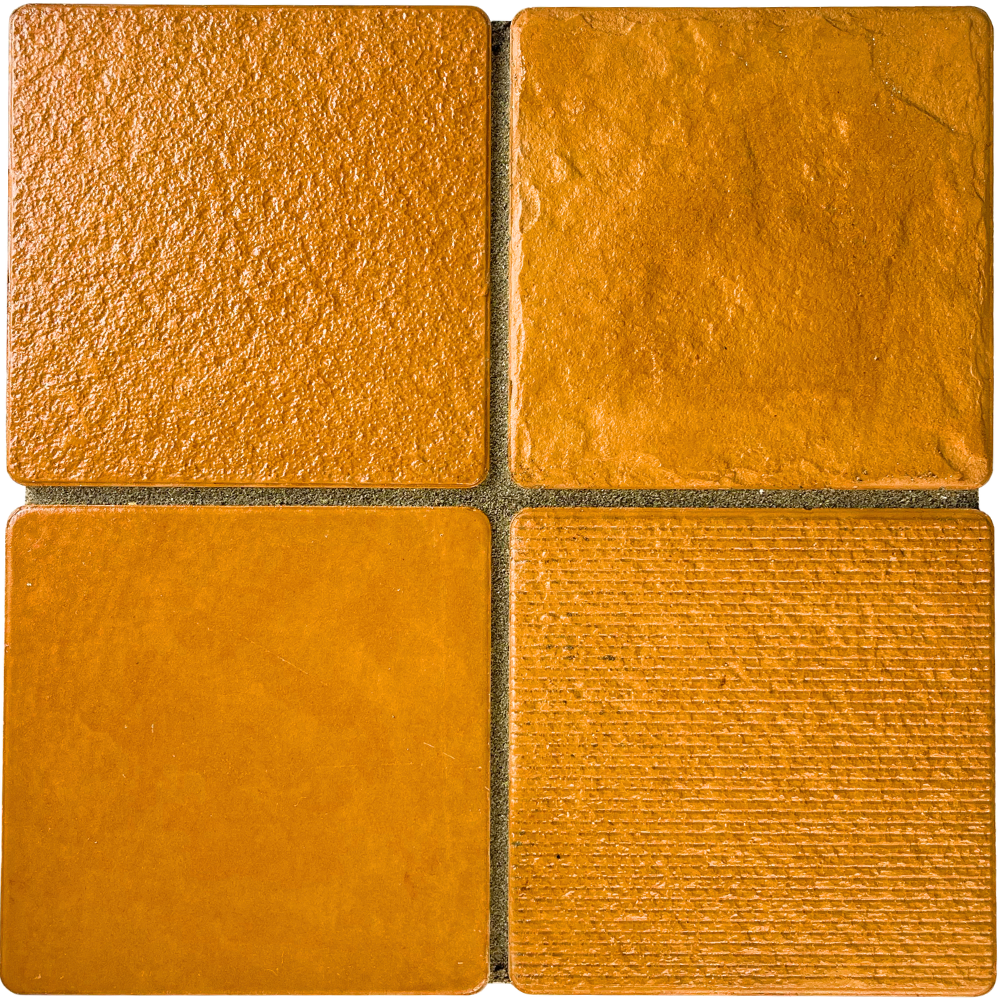

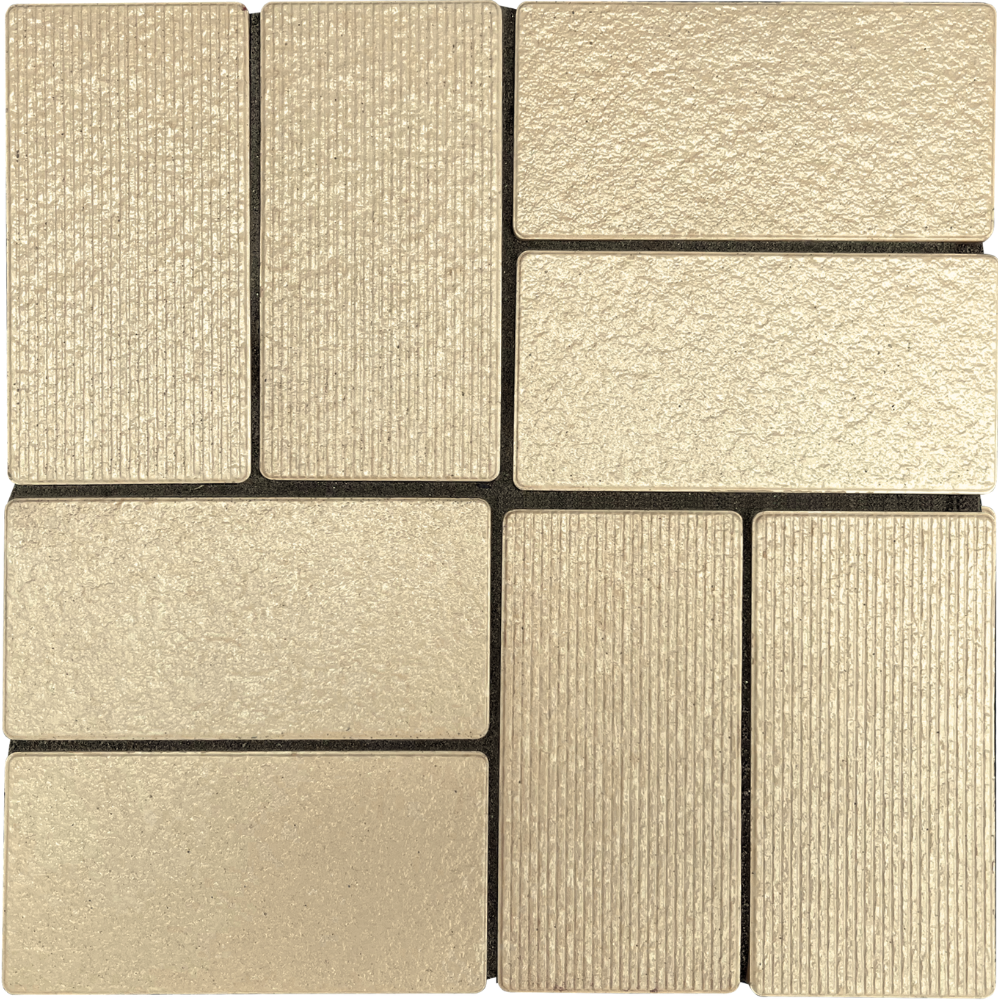

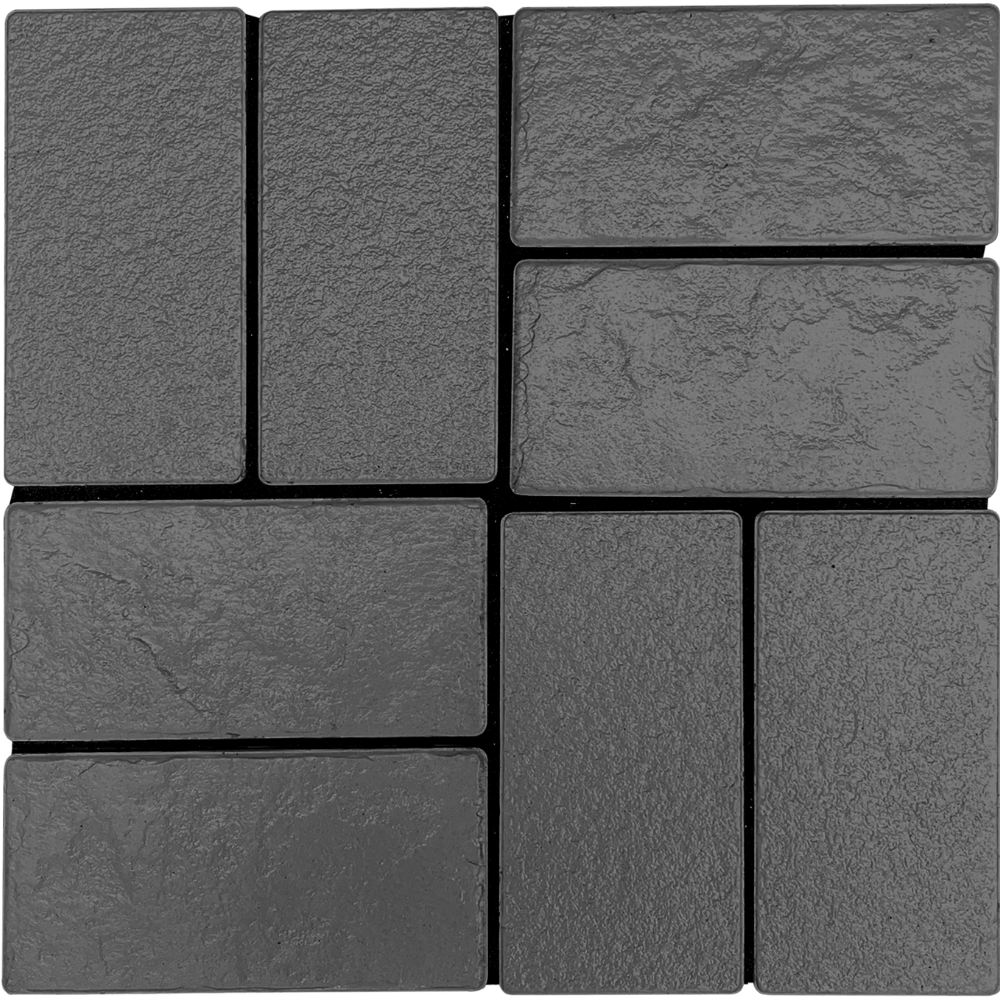

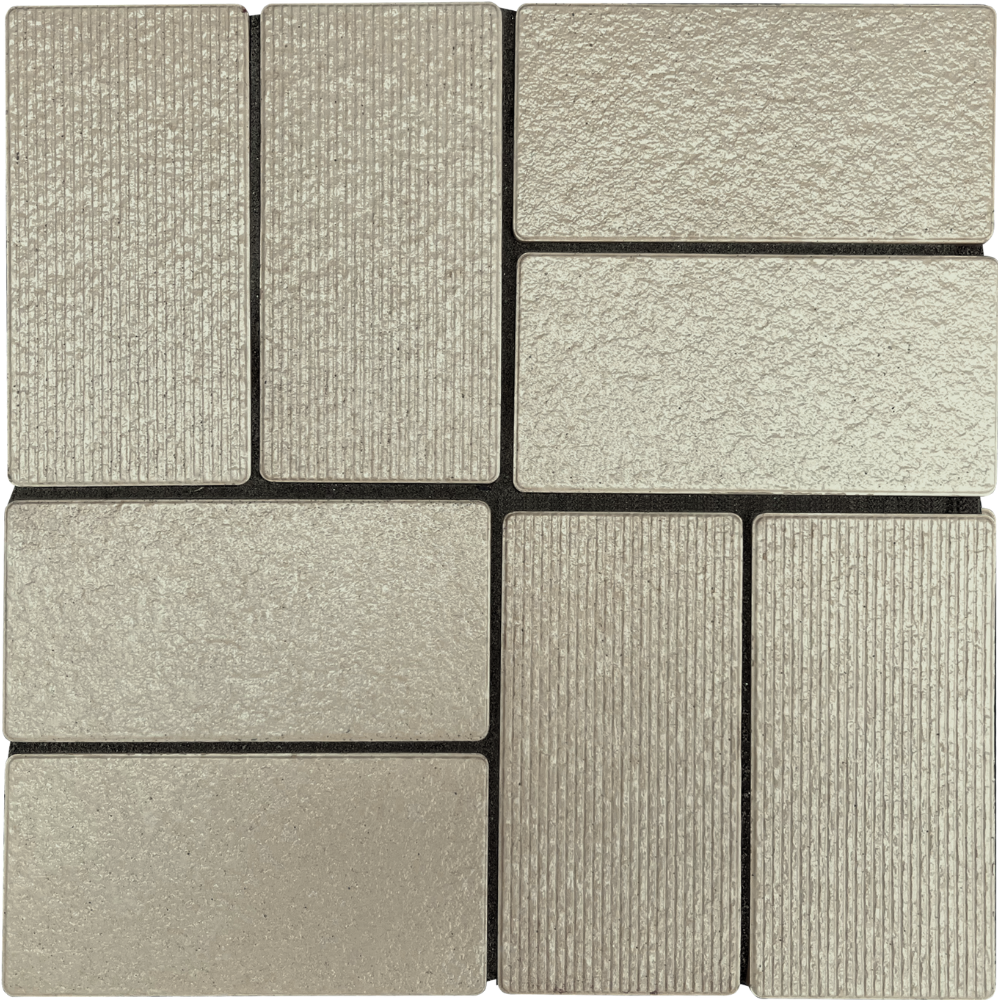

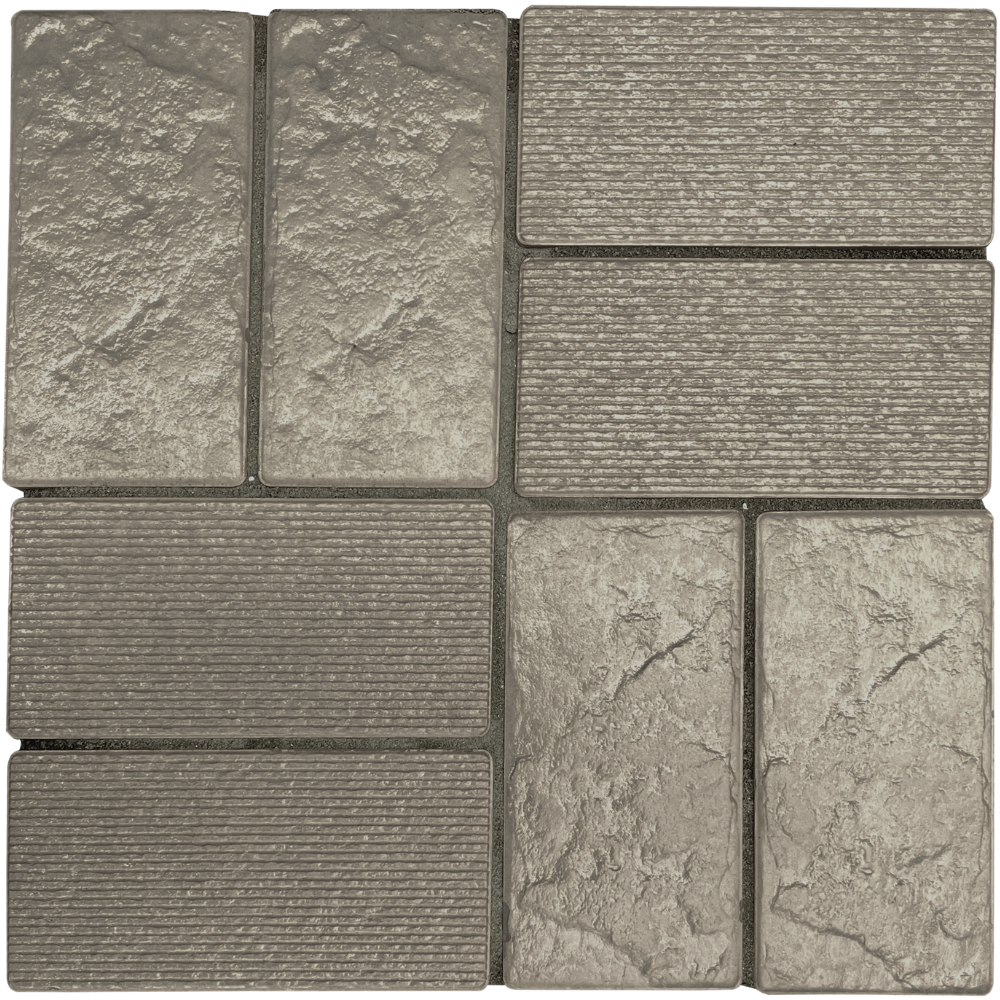

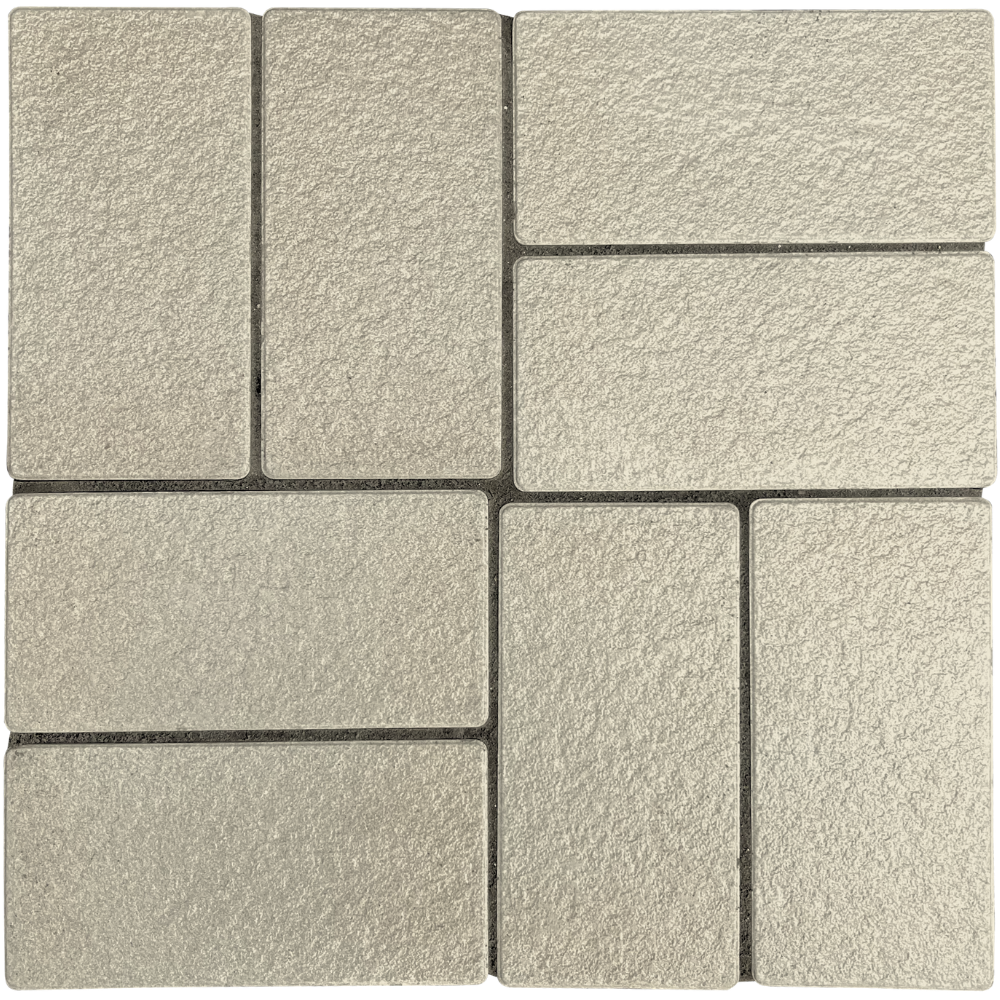

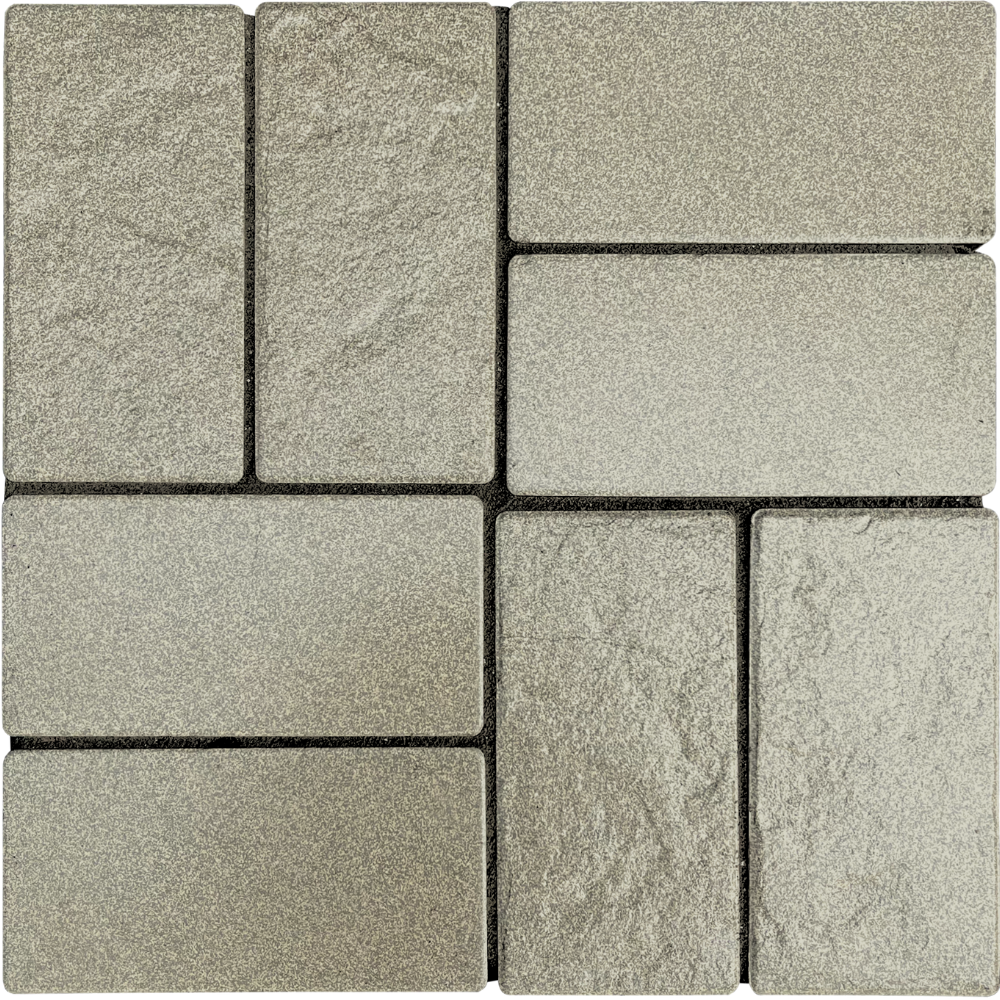

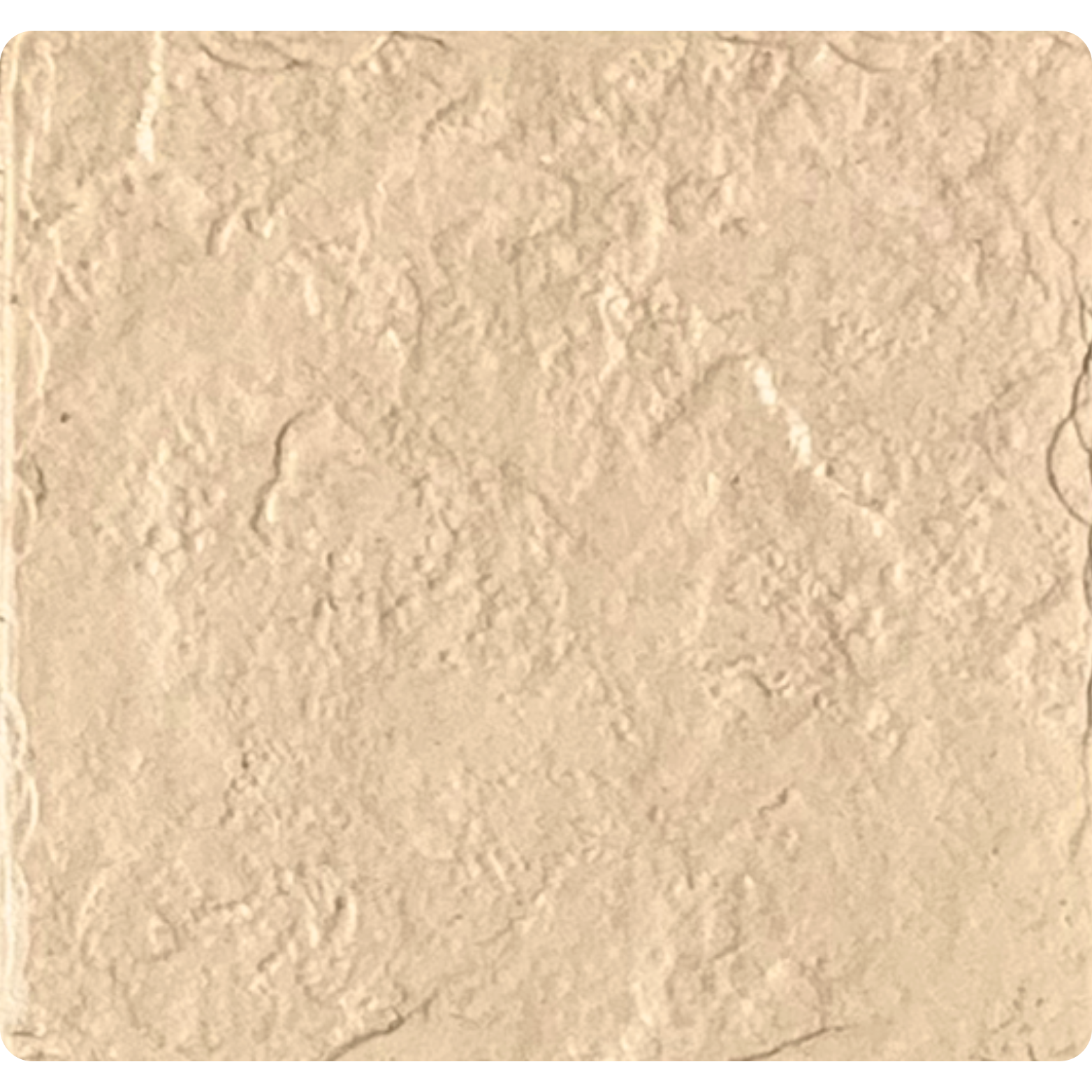

Unistone Claystone porcelain cobblestone combines the beauty of natural stone with the strength and precision of modern porcelain stone. Designed to replicate the authentic look and texture of hand-hewn natural stone, with irregularities in surface texture and edges, these tiles combine rustic charm with modern consistency for quick and easy installation.

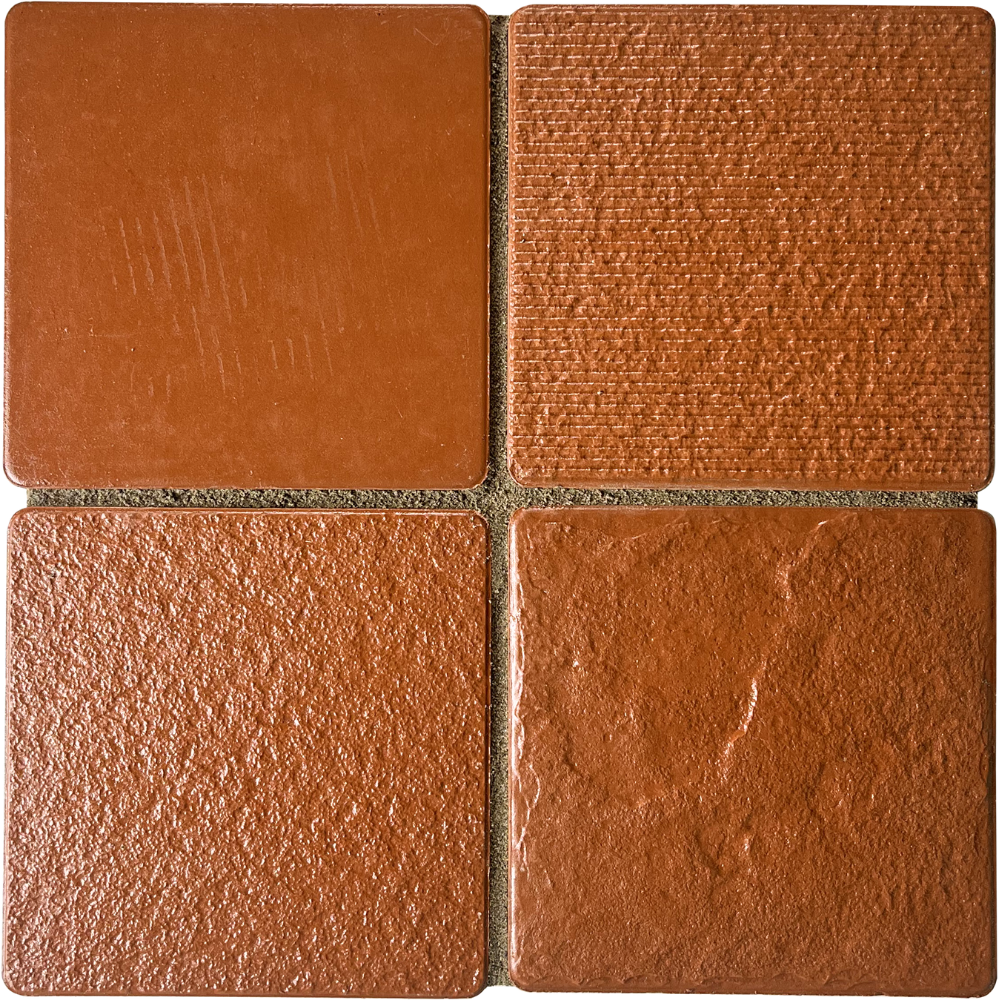

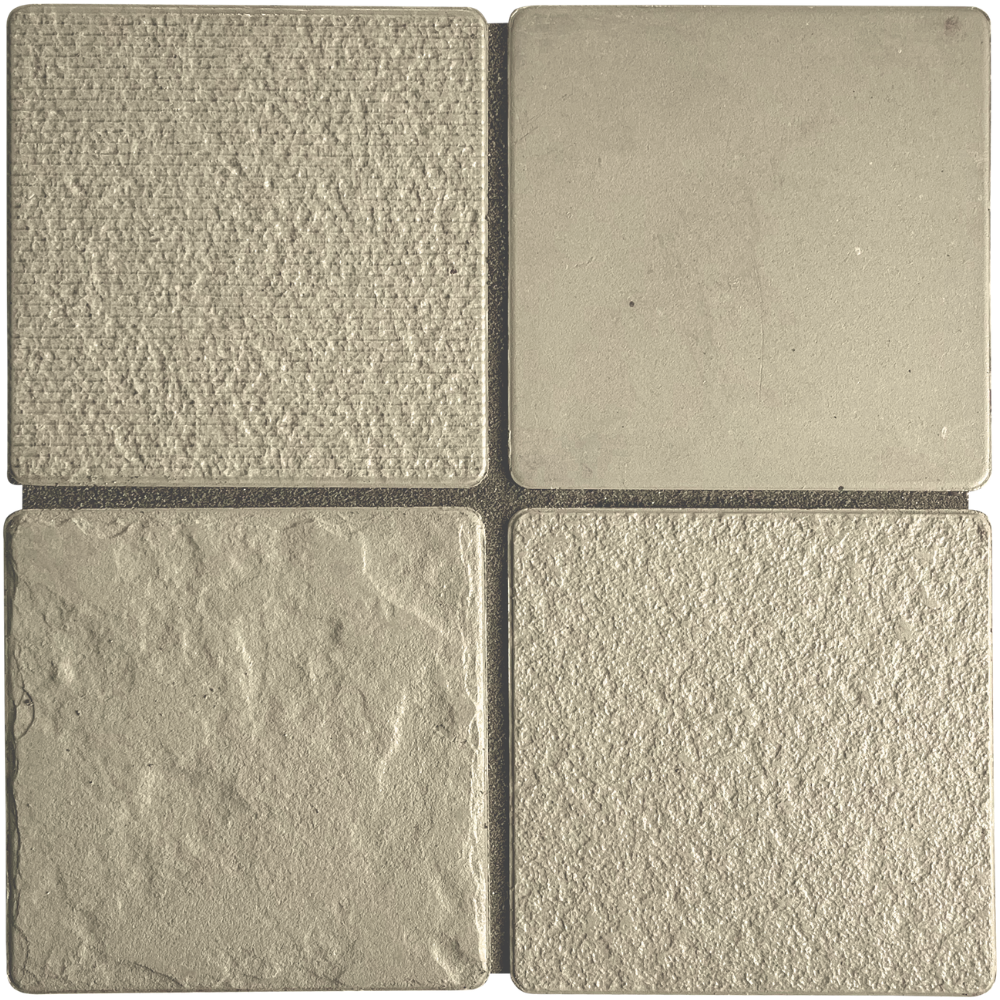

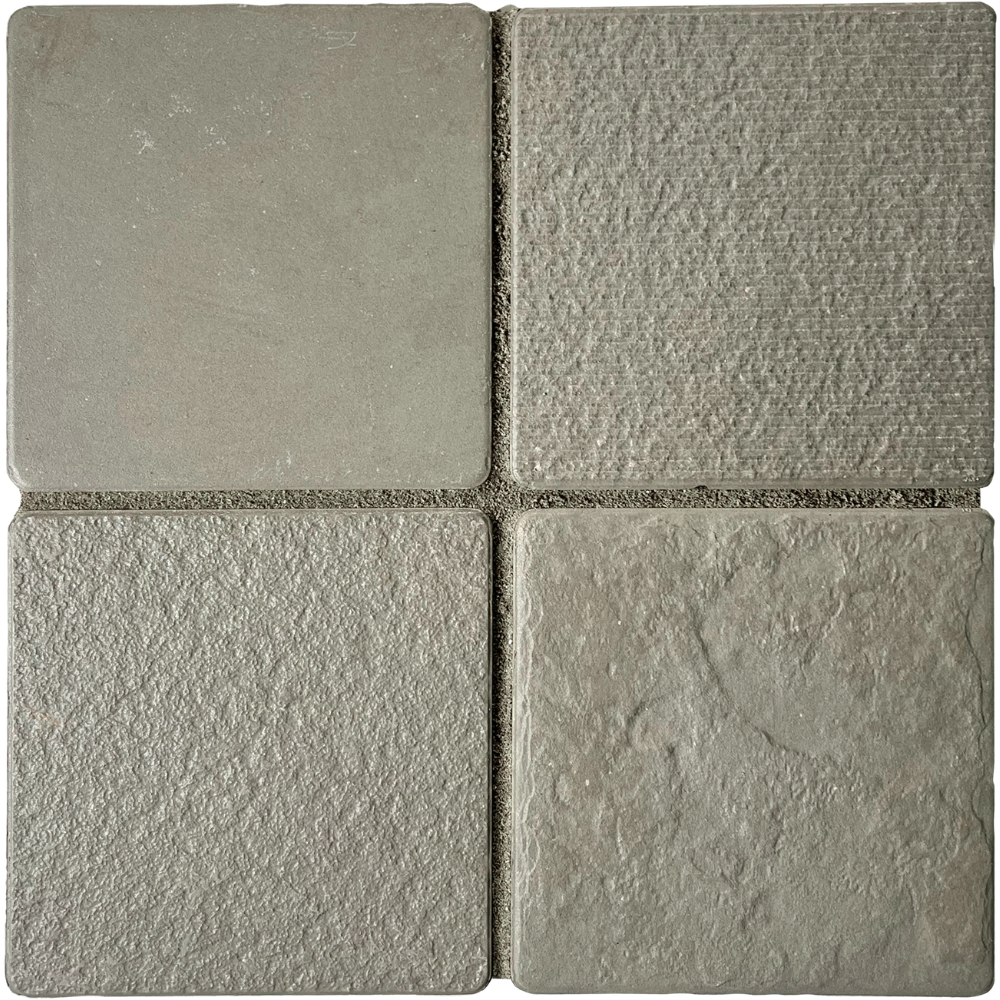

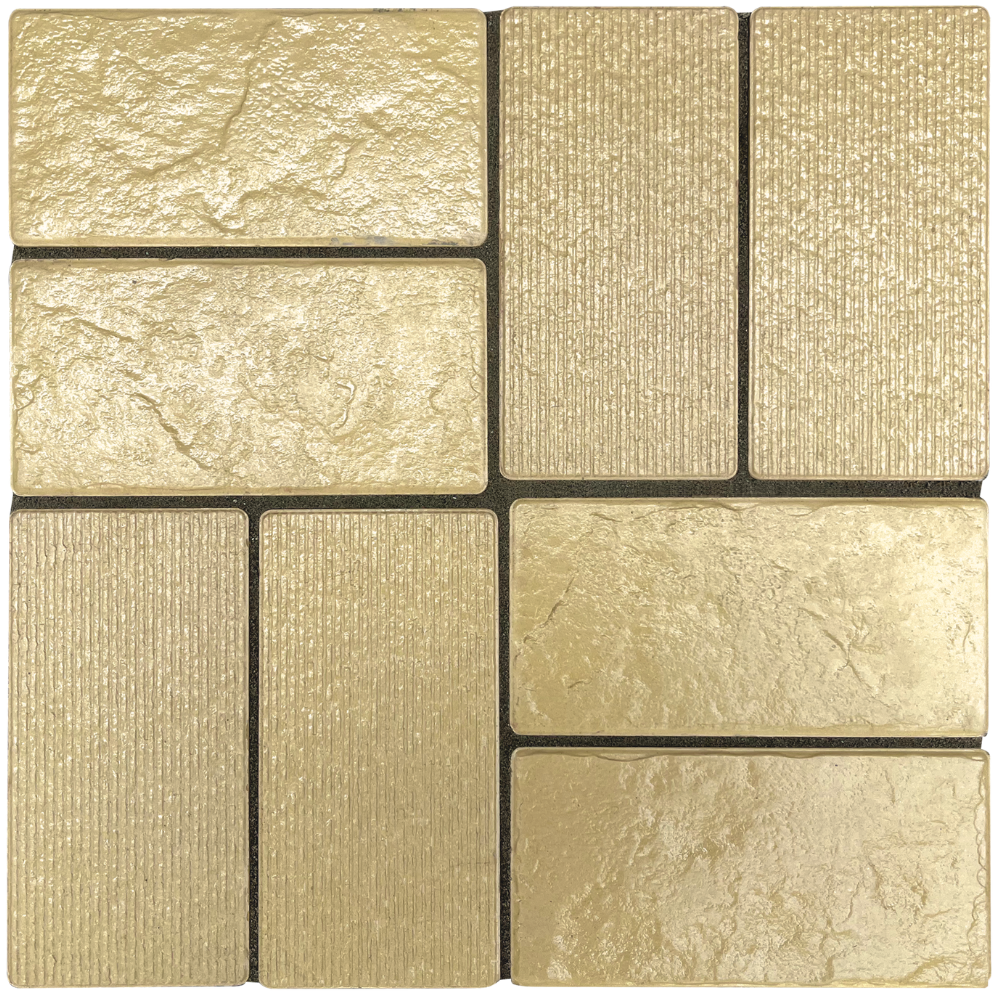

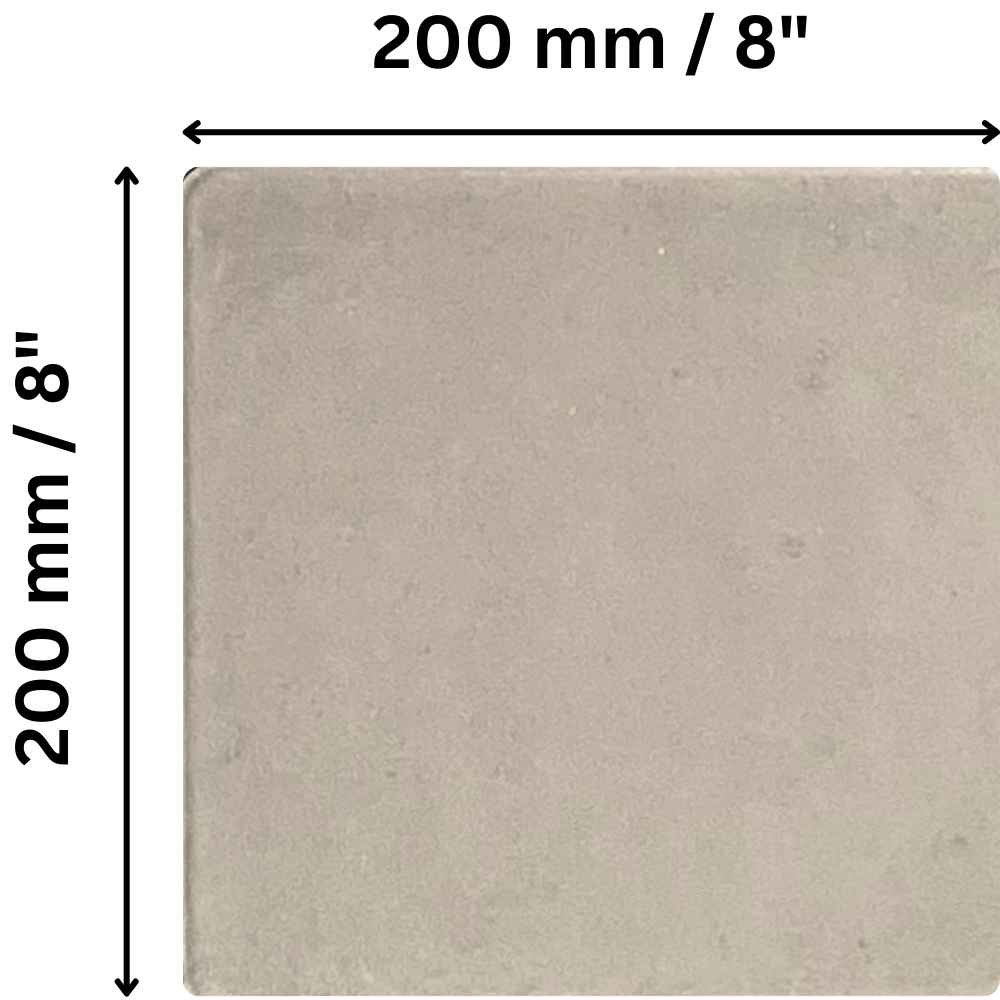

Manufactured from natural clay and fired at approximately 1150°C, Claystone is engineered for durability, performance, and long-term colour stability. Introduced for the first time in India, the range offers exceptional design flexibility with four formats, four textures, three thickness options, and two finishes—natural matt and Silky Glaze. Available in eighteen colours inspired by authentic and rustic tones, Unistone Claystone Porcelain Cobblestones provide architects and designers with a versatile paving solution that balances heritage aesthetics with modern reliability.

All Claystone tile sizes are nominal and non-rectified. The actual dimensions of the tiles may vary slightly from the stated sizes, with a permissible tolerance of ±3 mm. Such dimensional variations are inherent to the manufacturing process and contribute to the product’s natural, handcrafted appearance.

Claystone tiles must always be installed with joints / grooves of 8–10 mm to accommodate size variations and ensure proper load distribution and long-term performance. Fixing tiles without grooves is strictly not recommended, as a jointless installation may lead to alignment issues, stress concentrations, and reduced service life of the paving system.

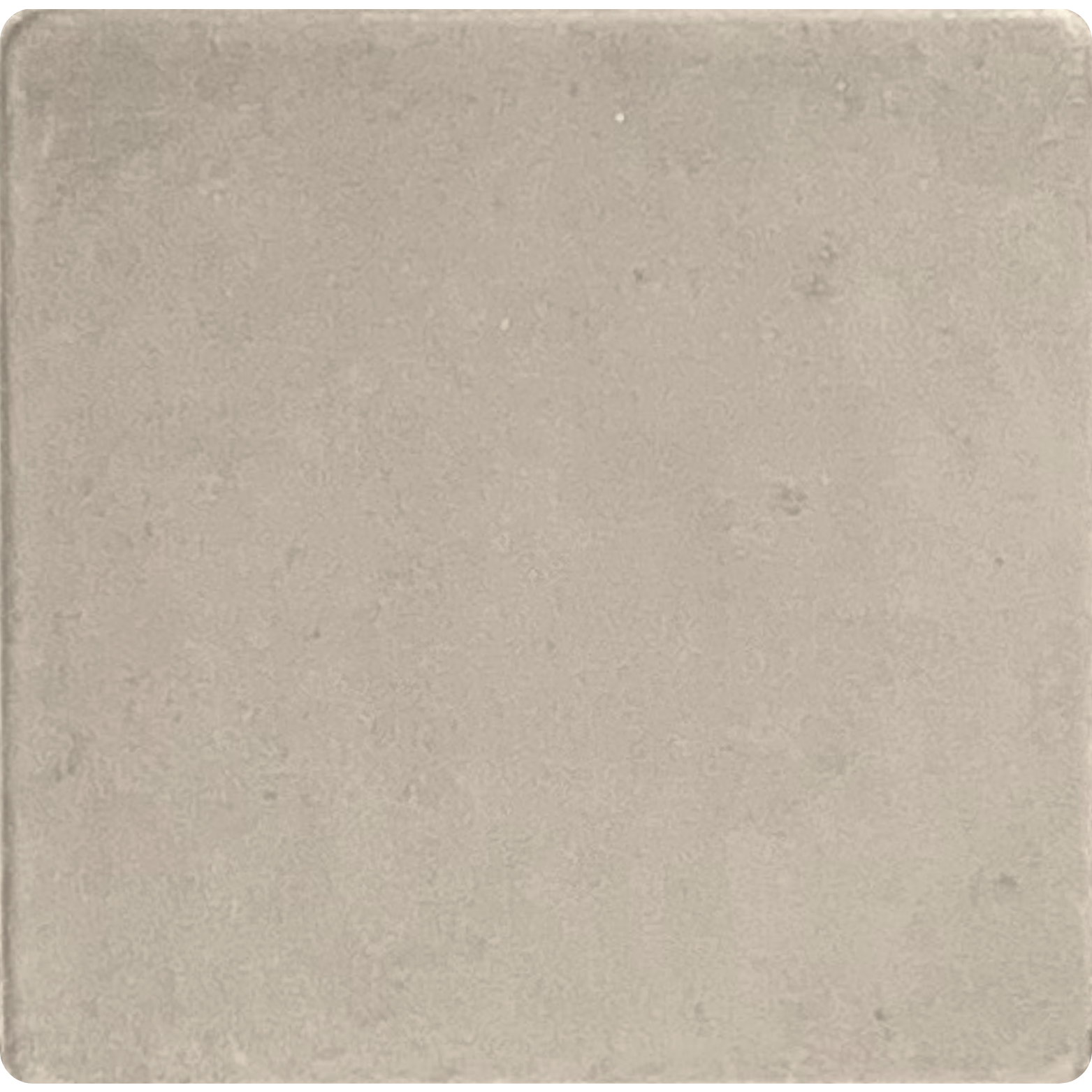

ClayStone tiles retain the natural non-rectified finish, keeping the authentic look of stone cobbles. The surface offers subtle textures, soft undulations, and earthy tones that replicate natural stone aesthetics while delivering the consistency of modern manufacturing. This makes each installation elegant yet practical, with a timeless rustic appeal.

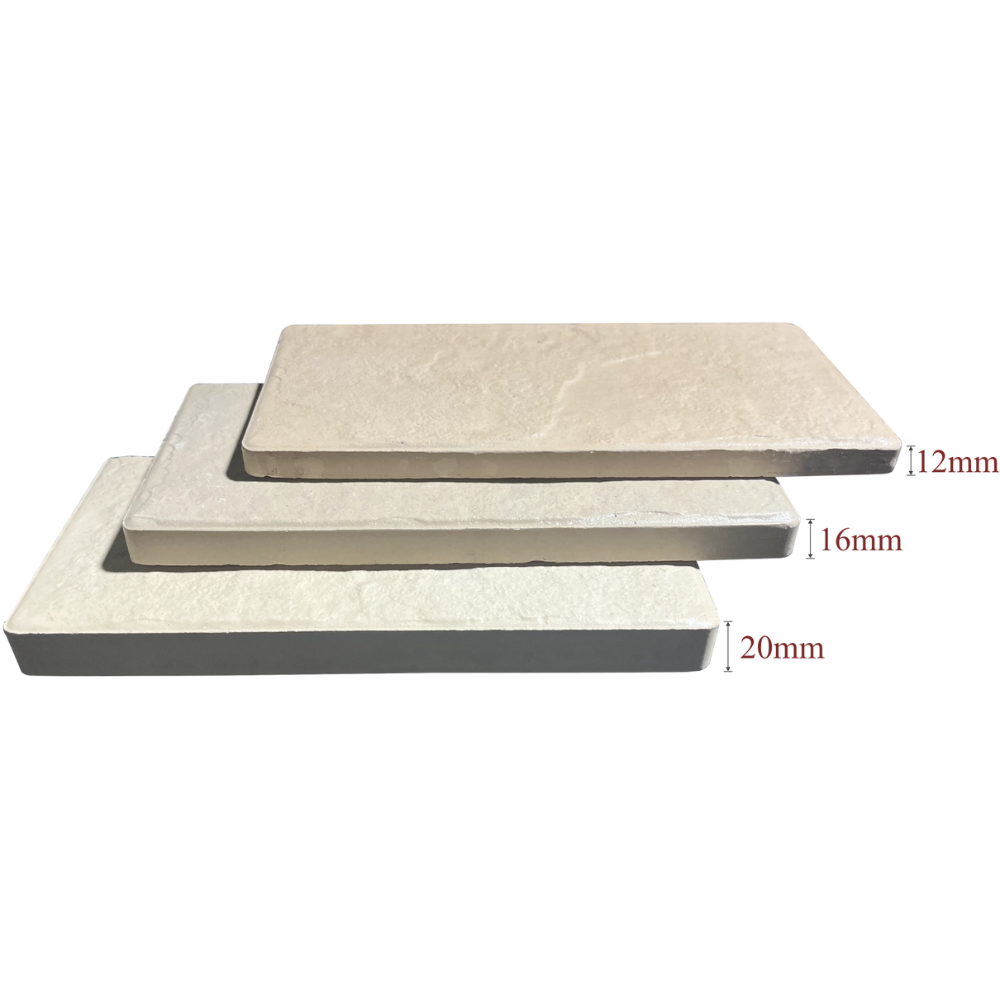

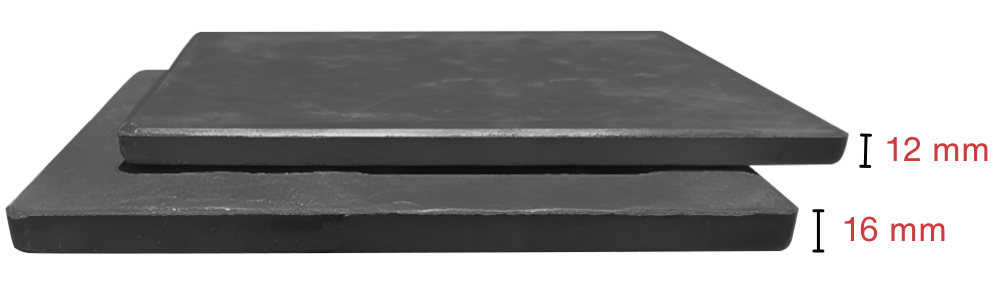

Unistone Claystone Porcelain Cobblestones are available in multiple thickness options, each designed to perform under specific load conditions. The 12 mm thickness is recommended for pedestrian traffic, making it ideal for walkways, plazas, courtyards, and landscaped areas. The 16 mm thickness is suitable for light vehicular movement, including car driveways and parking zones, where moderate load-bearing performance is required.

For heavy-duty applications, the 20 mm thickness is recommended and is suitable for truck loads. In areas subject to heavy fire-tender or emergency-vehicle loads, we strongly recommend using 20 mm thickness in the 6 × 6 size format only, as its square geometry offers superior load distribution. The 4 × 8 rectangular format, due to its shape, is not recommended for heavy fire tender traffic, even in 20 mm thickness. This format should be restricted to pedestrian and car traffic applications to ensure long-term performance and safety.

USAGE CHART | |

Traffic Category | Recommended Tile Specification |

Pedestrian Traffic | • 12 mm thickness – 4" X 8", 6" X 6", 8" X 8", 8" X 12" |

Light Vehicle Traffic | |

Heavy Vehicle Traffic | • 20 mm thickness – 6" X 6", 8" X 8" Regular Series • 16 mm thickness – 6" X 6", 8" X 8" Platinum Series. 4" X 8" size tiles to be used only for borders |

60-Ton Heavy Fire Tender Traffic | |

4. Border sizes such as 4″ × 8″ are not recommended for heavy traffic zones

5. The UniStone shall not be responsible for failure arising from:

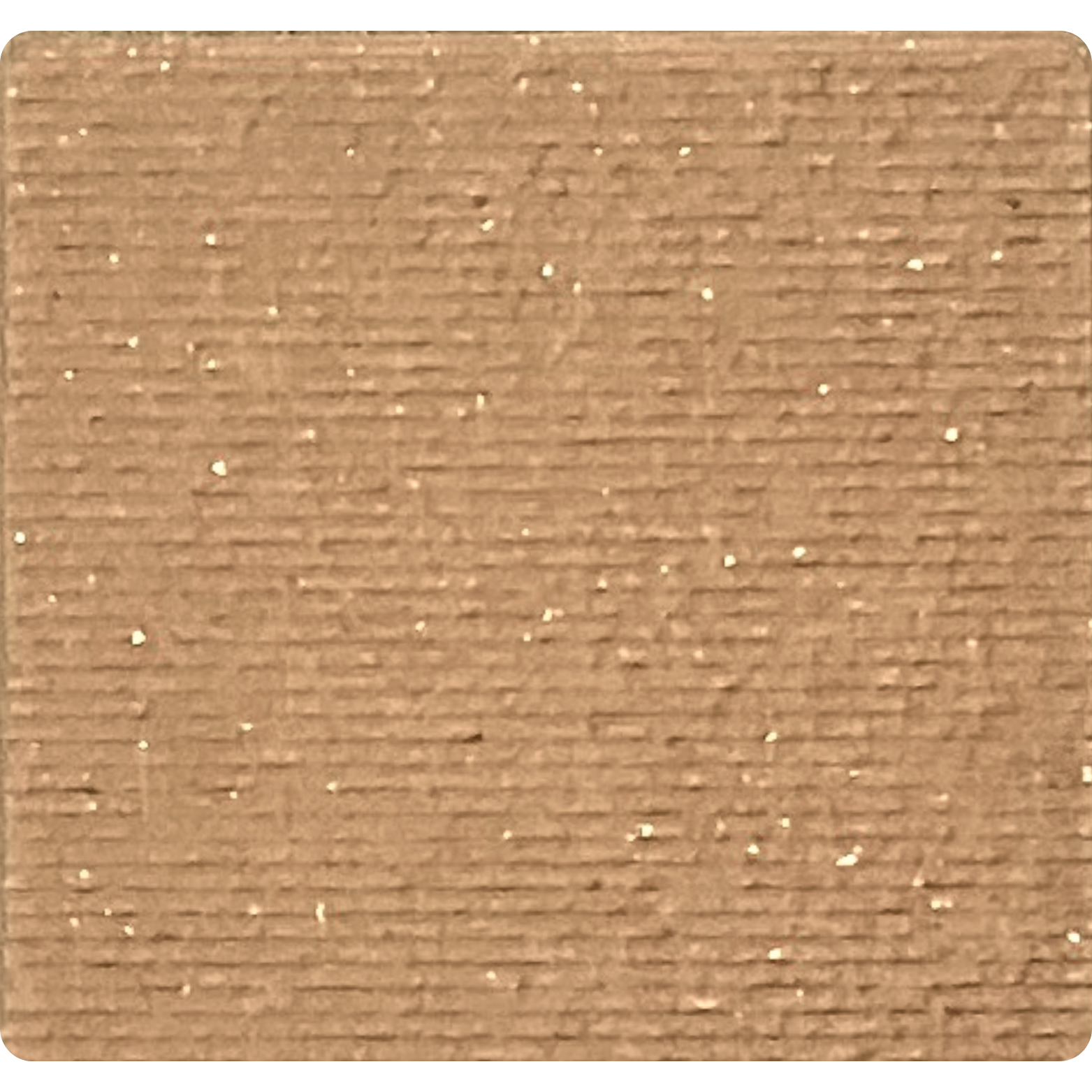

The Platinum Series represents the pinnacle of strength and performance within our paving portfolio. Engineered for the most demanding applications, this series combines exceptional durability with a refined, contemporary aesthetic.

The Platinum Series is the strongest tile series in our entire range.

Minor variations in colour may occur from batch to batch, and subtle differences can also be present within the same batch. These variations are an inherent characteristic of the manufacturing process and contribute to the natural, authentic appearance and visual richness of the product. Such tonal variation is considered a defining feature and an integral part of its design.

There may be a difference between the colours shown in the printed format and the actual samples. Please refer to the actual samples for a true representation of the colours.

Unistone, a leader in facades and paving, has pioneered innovative building solutions in India. In 1996, we introduced Reconstituted Stone, transforming architectural design. In 2007, we launched Customised GRC Products for modern construction, and in 2021, our CFP – Clay Facade Panel set new standards in energy-efficient, sustainable facades. Unistone remains at the forefront, delivering products that blend aesthetics, functionality, and durability.

17, Arihant Nagar, West Punjabi Bagh Opp. Metro Pillar No. 152-153, New Delhi - 110026

+91 8826457070, +91 8178713790